How Long It Really Takes to Manufacture Your Product: A Complete Timeline

If you’re developing a new product, one of the biggest questions you probably have is: How long will it take to manufacture my product?

The truth is, timelines vary depending on product complexity, manufacturing location, and order volume. But most delays don’t happen on the factory floor, they happen because brands underestimate the time required for design, prototyping, approvals, compliance testing, and logistics.

In this guide, we’ll walk you through a realistic timeline for manufacturing a product and highlight what can speed things up (or slow you down).

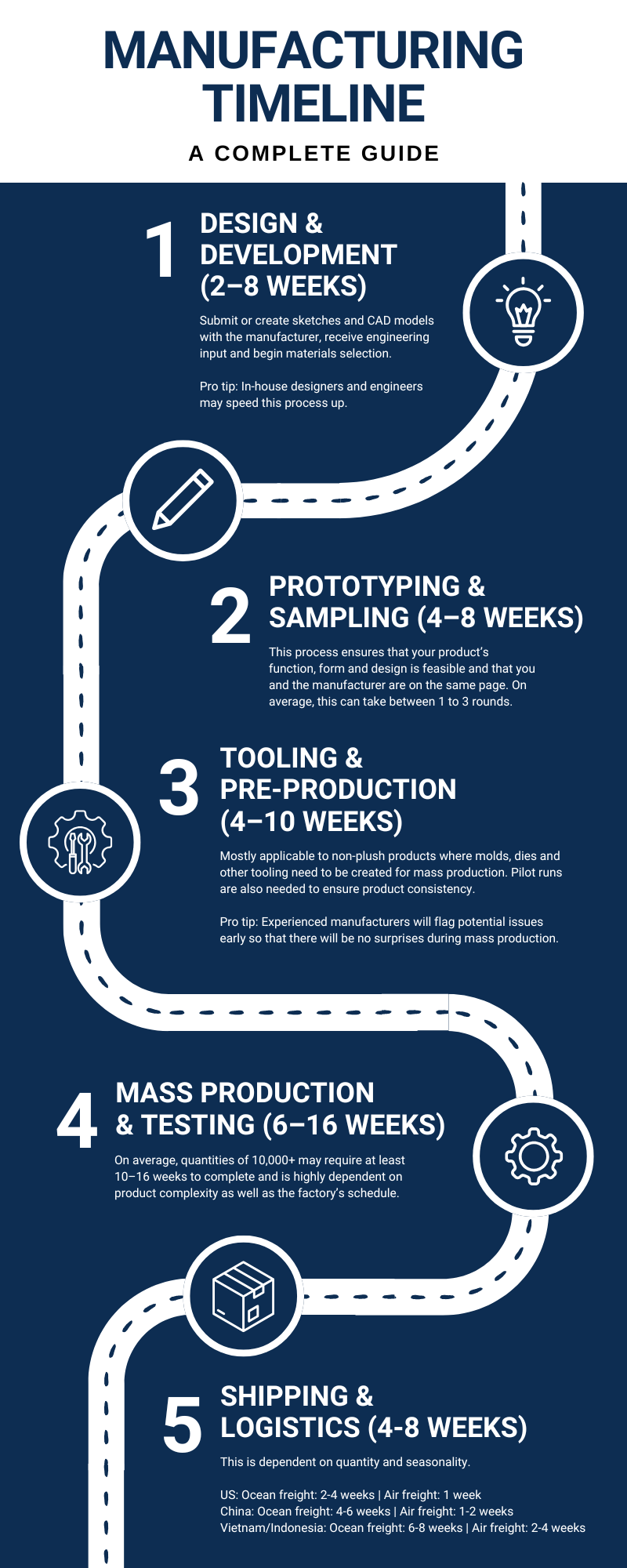

Stage 1: Design & Development (2–8 Weeks)

Before a factory touches your product, your idea needs to be translated into technical specifications.

Industrial Design: Sketches, CAD models, and early concepts.

Engineering Input: Ensuring your product is functional and manufacturable.

Material Selection: Picking fabrics, plastics, metals, or electronics.

Pro Tip: Brands with in-house designers and engineers may move faster.

Stage 2: Prototyping & Sampling (4–8 Weeks)

This stage is where you turn your design into something you can touch and test.

Prototypes: Early versions to validate function and form.

Samples: Factory-made models to prove production feasibility.

Revisions: Adjustments to fix design flaws or optimize usability.

Each iteration adds 2–4 weeks, depending on complexity and shipping speed (domestic vs overseas).

Reality Check: Many brands need 2–3 rounds of samples before final approval. Skipping this process risks expensive production mistakes later.

Stage 3: Tooling & Pre-Production (4–10 Weeks)

For custom products, factories need to build molds, dies, or tooling before mass production can begin.

Simple tooling: 3–4 weeks.

Complex molds (plastics, injection, precision parts): Up to 10 weeks.

Pilot runs: Small test batches to ensure consistency.

Pro Tip: This is often where hidden costs and delays show up. An experienced manufacturer will flag potential issues early, for example, they will have their engineers run pre-production checks to uncover risks before they become costly problems.

Stage 4: Mass Production (6–16 Weeks)

Once tooling is complete and samples are approved, your factory can begin full-scale production.

Timeline depends on:

Order Volume: Small runs (500–1,000 units) can take 6–8 weeks, while large runs (10,000+) may need 12–16 weeks.

Product Complexity: Simple textiles move faster than electronics or multi-component products.

Factory Schedule: Busy seasons (before Christmas, Chinese New Year, Thanksgiving, China’s Golden Week) often add delays.

Stage 5: Shipping & Logistics (4–8 Weeks)

Getting your products made is only half the journey — you still need them delivered. This step can vary depending on the method, seasonality and customs clearance.

Shipping domestically in the U.S.: 2-4 weeks

Shipping from China:

Ocean freight: 4–6 weeks (plus customs clearance).

Air freight: 1–2 weeks, but at a much higher cost.

Shipping from Vietnam or Indonesia:

Ocean freight: 6-8 weeks (plus customs clearance).

Air freight: 2-3 weeks, but at even higher cost.

How to Plan for a Successful Timeline

Here are three ways to stay on track:

Build Buffer Time: Add 20–30% extra time for unexpected delays.

Work with Experienced Manufacturers: A seasoned partner will flag risks and guide you through realistic scheduling.

Align Your Launch Goals: Back into your production start date based on when you need inventory on shelves or online.

Request a free consultation today and let us help you bring your product to market faster, smoother, and with fewer surprises.

Conclusion

The real timeline of manufacturing your product isn’t just about factory work — it’s about planning for design, prototyping, tooling, production, and logistics.

By setting realistic expectations, building in buffer time, and partnering with an experienced manufacturer, you’ll avoid missed deadlines, rushed quality issues, and costly delays.

The result? A smoother, more predictable path from idea to launch.

If you missed it, read part one and two of this manufacturing how-to series: How to Find the Right Manufacturer and The Real Cost of Manufacturing Your Product so you have a complete overview of what it takes to bring your product to life.